Gold Wash Plants

Star Trace offering the Gold Wash Plant in the remarkable qualities with latest technology. Star Trace manufacturing a several different types of gold wash plants from 50-500tons per hour. In all conditions each plant consists of proportionate sized of 3 sluice boxes and utilized 3 different types of riffle designs.

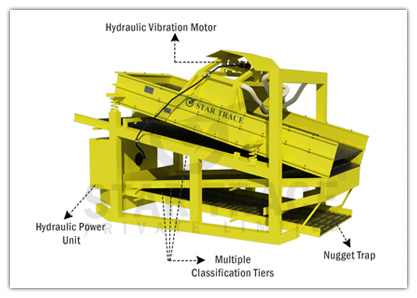

Star Trace Gold wash plant is a complete portable plant, no need to setup additional sluice boxes or separators in the plant. In the top of the plant, grizzly bar section it will take up to 36 inch rocks. The classification begins when the material is placed on the grizzly bar and the high pressure of water should separate the smaller material from the larger rocks. Then the separated material is dropped below to enter into the sluice boxes and the large rocks are disposed. It consists of 3 independent adjusting sluice boxes. To collect the nuggests, most of the materials continues through the smaller area while at the nugget trap allows larger materials to bypass the system to rejoin at the final stage for sluicing.

Discharge ConveyorThe cleaning out of the machine is very easy, efficient and quick. By using the spin clamps that release the trays to reveal the miners moss below.

Clean UpStar Trace Gold wash plant is fully hydraulic with no needed of electricity. Our device are driven directly by the hydraulic motor with no chain or belt drives for the shaker weight, which some mechanical parts need to be break down.

Drive SystemStar Trace hydraulic system is lower fuel consumption with less mechanical breaking points. Our machines are used in the shaker system that come with fully equipped grease points which leads to use for many years. For more portability, the machines are highly portable and can be mounted on trailers.

Features- Commercial quality at Cost effective

- Long life, heavy duty equipment

- Reliable machine

- Highly portable

- No additional recovery equipment needed

- Turnkey operations available

- Free maintenance